Piercing Safety

Lets talk about that safety a bit!

“It is the position of the Association of Professional Piercers that only sterile disposable equipment is suitable for body piercing, and that only materials which are certified as safe for internal implant should be placed in inside a fresh or unhealed piercing”

All piercings that are done here at Tradition are all single use needles, single use tools, and sterilized instruments at the time of the piercing. The shop is fully disposable. Nothing is reused.

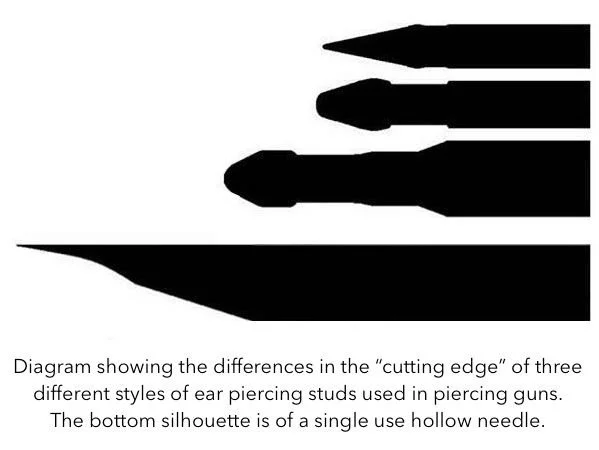

While piercing guns may seem to be a quick, easy and convenient way of creating holes, they have major drawbacks in terms of sterility, tissue damage and inappropriate jewelry design.

Piercing guns create significant tissue damage often resulting in poor healing, excess scarring, and are unfortunately more painful. They create blunt force trauma to the ear causing more swelling and issues during the healing process. Ear piercing guns usually use jewelry that is not certified by the FDA, ISO, or ASTM as safe for long term wear in the human body.

This is why we pierce with needles. Since they’re much sharper than gun piercing jewelry, they go through with ease meaning less discomfort during the process. Needles will create a precise opening for jewelry to be inserted resulting in less swelling and damage overall. By far the safest and least painful method to get a piercing. Our jewelry is verified and safe to use for long term wear in the human body which is all sterilized at the time of your piercing.

The jewelry we use is ALWAYS Implant Grade. The materials we use here are usually Implant grade Steel that is ASTM F-138 or ISO 5832-1 compliant, Alloyed Titanium (Ti-6Al-4V) that is ASTM F-136 or ISO 5832-3 compliant, Niobium that is ASTM B392 compliant. The jewelry we use is the same grade of material suitable for medical implants and devices. These materials go through a rigorous testing process to ensure bio compatibility. Body jewelry companies supply us with material test certificates. These are made at the melter during their specified tests by technicians accredited by the regulatory authority. These certificates refer to ISO and ASTM International Standards for implants. The Association of Professional Piercers also have their own body jewelry verification program. This requires body jewelry companies to meet stringent quality and safety standards, aligning with the Body Jewelry Verification Program’s goals. This badge is not a hard line and not all companies need it. Its just an extra verification program that the APP has recently introduced.

For every piercing we perform here at Tradition, We use an autoclave to sterilization anything we may need at the time of the piercing. The machine we use is a SciCan Statim 2000. It’s a cassette style autoclave using heat, steam and pressure for a controlled amount of time to sterilize anything we might need at the time of the piercing. Since we sterilize what we need, when we need it, there is no need for sterilization pouches. Any instruments used inside of pouches have been pre sterilized and verified with tracking and lot numbers to ensure safety. Our machine is tested monthly to ensure proper function and sterilization.

Here we have an example of equipment validation that we do here. This test strip is called a steam chemical integrator strip. This test strip validates that our autoclave has reached the proper temperature, pressure, and time to properly sterilize anything we use.

Another example is equipment validation is our monthly spore testing. This is a test that we perform on our autoclave on a monthly basis. We run a test stripped through our autoclave and send it to a third party company that analyzes the spore test to make sure our autoclave is working efficiently

We go through great lengths to ensure the safety and sanitation of every part of the piercing process. I hope you to see you and help you have a safe fun and awesome piercing experience!